Ordering a One-off Aluminum Case for Custom Keyboards

Introduction

3D printed cases and sandwich plate cases are commonly used in custom keyboards with a smaller user base. CNC aluminum cases cost higher and some manufacturers require a minimum order quantity. But, it is possible to order a one-off CNC’ed custom aluminum case for your keyboard now.

Make Changes

The Zerosprey42 case is modified from the 3D printable case at the Osprey repo, created by propagandalf. I used Fusion 360 to modify the STEP files, but you can use any 3D modeling tools.

Here is an important change when the case is CNC’ed instead of 3D printed. Heatset threaded inserts are used in the 3D printable case. The holes are bigger. But for CNC aluminum, tapped threads are used. The screw holes were changed from 3.2mm in diameter to 1.6mm for M2 tapped threads.

Here are the other optional optimizations. The height of the top case is a bit too tall, as my thumb hits the case while I type. The height of the top case is lowered.

The Zerosprey42 is a wired keyboard without power switches, while the original Osprey requires a power switch. So the opening for a power switch is removed.

Test it

The cost of CNC aluminum machining is very high. It’s recommended to 3D print the prototype for testing using a low cost FDM 3D printer. Alternatively, you can use 3D printing services using PLA (FDM), or Resin (SLA).

Get a Quotation

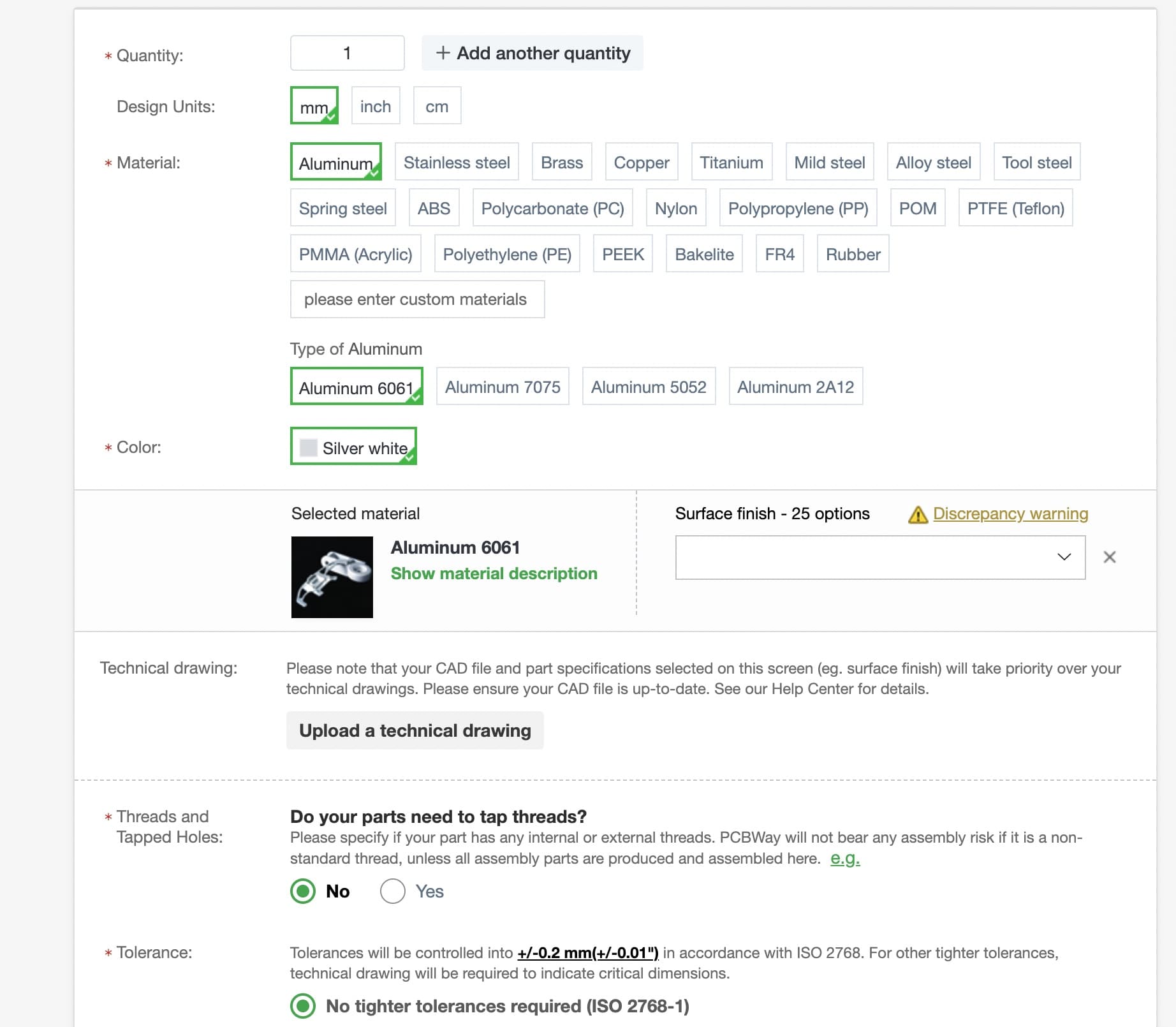

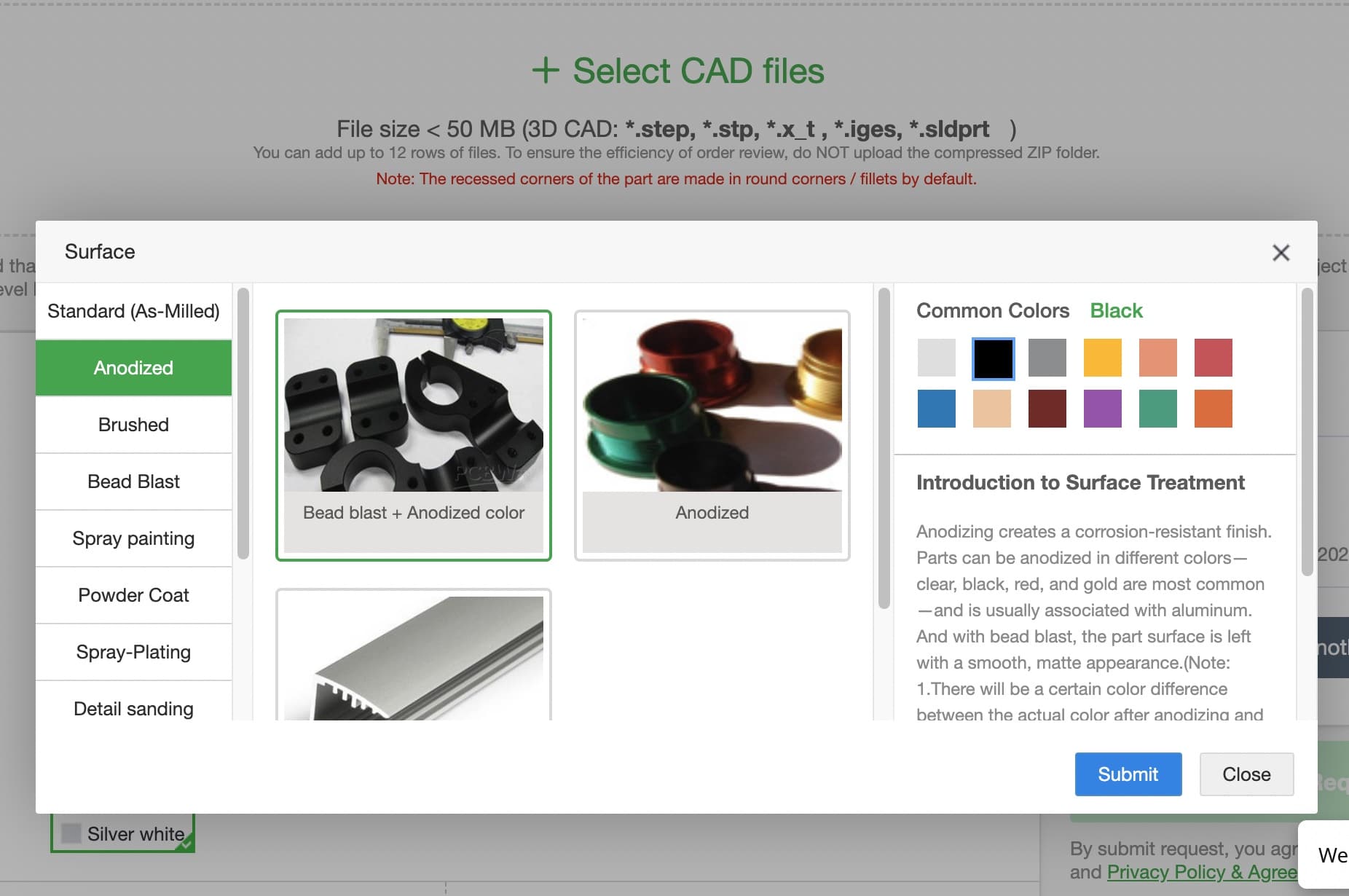

Similar to ordering PCBs or 3D printed parts, ordering CNC parts can be daunting because there are many options in the quotation screen. A lot of the options can be kept by default.

Here’s the screenshot for the CNC machining ordering page at PCBWay.

The options I have chosen are

- Material: Aluminum 6061

- Surface Finish: Bead blast + Anodized color (black)

- Threads and Tapped Holes: Yes

For the tapped threads, you will need to upload a drawing to specify the holes. A technical drawing similar to that on Bakeneko 60 V3 by kkatano, or a simple drawing can be used.

Place the Order

After submitting the request, a quotation will be available shortly. Unlike traditional quotation that takes days, a quotation from PCBWay will be provided within hours.

It took around 7 days for the product to be manufactured.

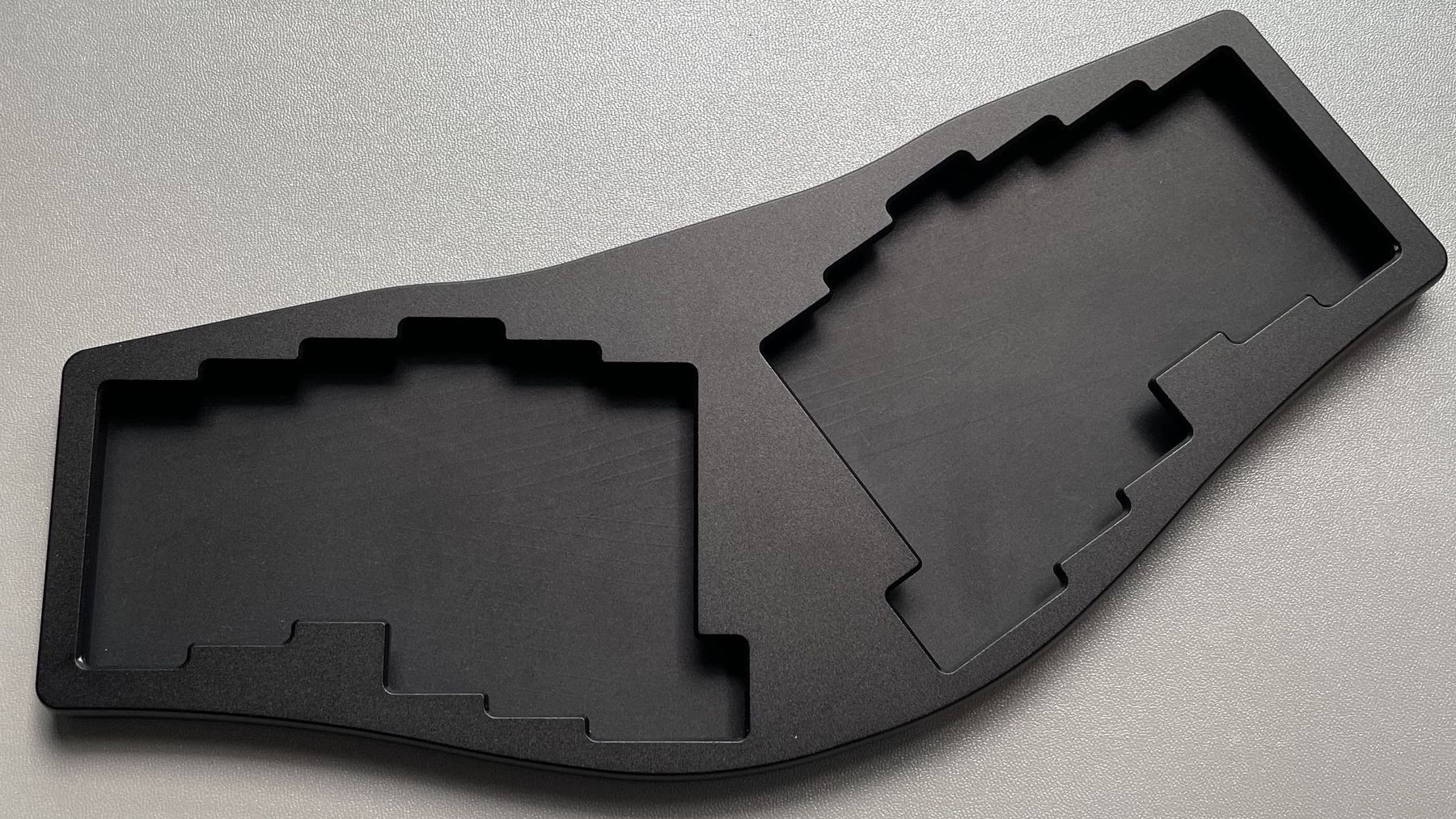

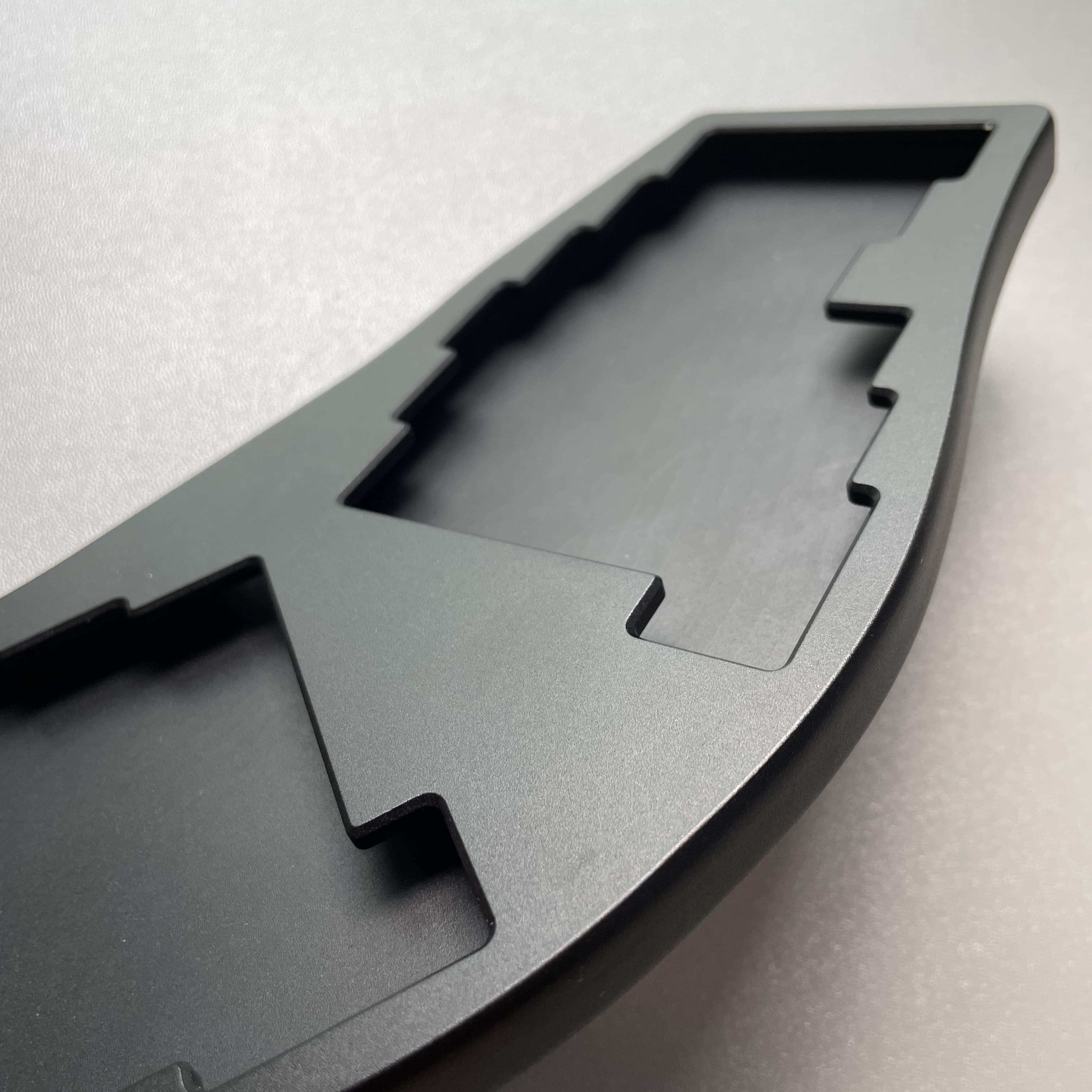

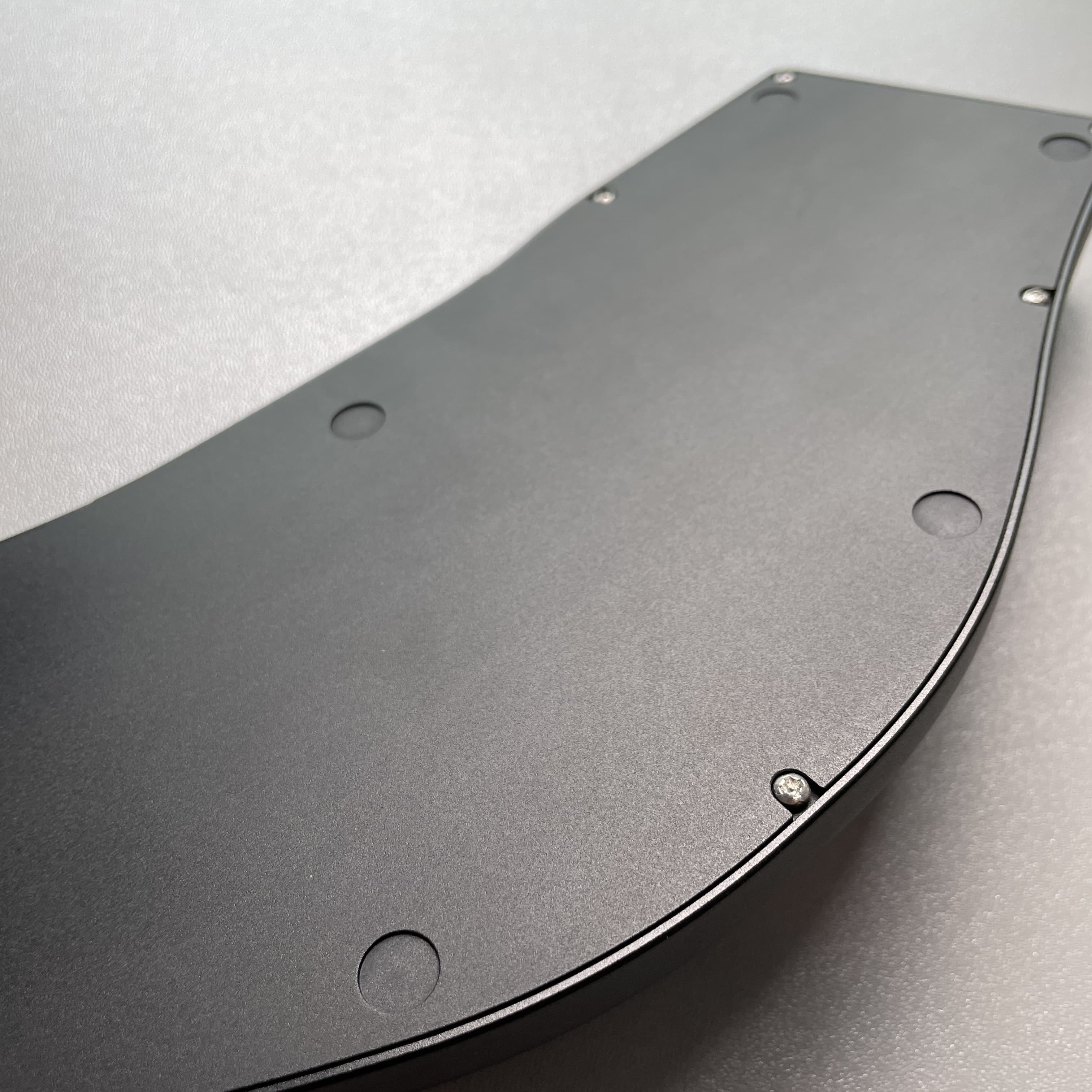

Photos of the Final Product

The top / outer surface finish is very smooth without defects.

The top and bottom case can be perfectly aligned and assembled.

The screws are tested and assembled by PCBWay before shipping. As expected, there are some minor marks as mentioned in the surface finish description.

Final Words

The ordering process was smoother than expected. If you missed a group buy, or if you want to order a one-off custom aluminum case for custom keyboards, you can place a one-off order

This post and the prototype are sponsored by PCBWay.